Melting Alloys

Carbon Steel, Alloy Steel, Stainless Steel, Copper Based Alloys, Duplex Steel Alloys & Super Alloys like Hastalloy, Stellite & Monel Matching ASTM, AISI, DIN, GOST, JIS, BS, SAE & IS standards

Weight and Size Limit

Weight: 10 grams – 51 Kg.

Size : 350MM Length X 350mm W X 350MM hight

Citrate shape in parts.

Tolerance

| Permissible Deviations on Dimensions, as per IS 11166:1993 Class 2 | ||||||||||

| Nominal Dimensions | Overall Dimensions in mm. | Center Distance Tolerance For Holes & Bosses | ||||||||

| of Rough Casting | Up to 6 | Over 6 | Over 10 | Over 18 | Over 30 | Over 80 | Over 180 | Over 300 | ||

| Over | Up to | Up to 10 | Up to 18 | Up to 30 | Up to 80 | Up to 180 | Up to 300 | Up to 500 | ||

| 6 | ± 0.10 | ± 0.12 | ± 0.15 | ± 0.20 | ± 0.25 | ± 0.25 | ± 0.30 | ± 0.35 | ± 0.12 | |

| 6 | 10 | ± 0.12 | ± 0.15 | ± 0.25 | ± 0.25 | ± 0.30 | ± 0.35 | ± 0.45 | ± 0.12 | |

| 10 | 18 | ± 0.20 | ± 0.30 | ± 0.35 | ± 0.35 | ± 0.40 | ± 0.55 | ± 0.15 | ||

| 18 | 30 | ± 0.30 | ± 0.40 | ± 0.45 | ± 0.50 | ± 0.65 | ± 0.25 | |||

| 30 | 80 | ± 0.55 | ± 0.55 | ± 0.60 | ± 0.75 | ± 0.35 | ||||

| 80 | 180 | ± 0.60 | ± 0.70 | ± 0.90 | ± 0.45 | |||||

| 180 | 300 | ± 1.00 | ± 1.15 | ± 0.70 | ||||||

| 300 | 500 | ± 2.00 | ± 0.90 | |||||||

Minimum Order Quantity

Minimum 60 kg casting for non regular material grade

Surface Finish:

Surface finish of our Castings will be 1.6 RA Value.

Tools Design and Manufacturing

- In house well equipped design tool room to manufacture multi-cavity complex dies.

- Associations with tool rooms equipped with CNC wire cut, spark erosion, 3D pantograph machine.

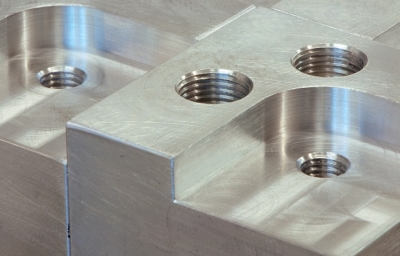

ValueAddition

- CNC & VMC Machining

- NDT – RT / MP / LP

- All types Special Heat treatment

- All types Physical tests

- Additional Tests – Surface roughness test, Salt spray test, IGC Practice B, F, Impact Test

- Coating – Zinc passivation, Electro Polishing, Acid Pickling, Blackening